Understanding Kitchen Cabinet Dimensions and Paint Needs

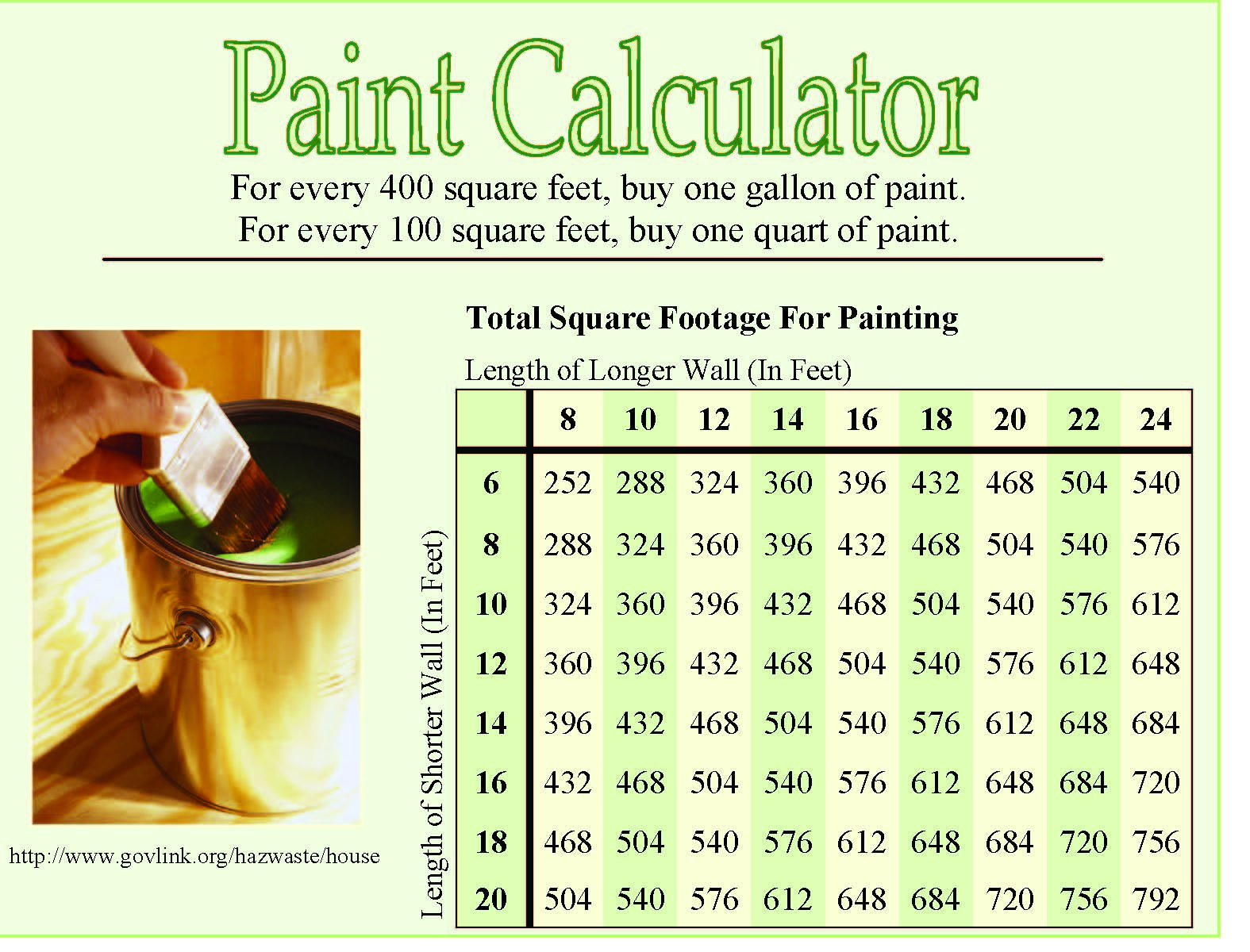

Accurately measuring your kitchen cabinets is crucial for determining the correct amount of paint needed for a successful painting project. Underestimating the required paint can lead to uneven coverage and the need for additional coats, while overestimating can result in wasted resources. This section provides a comprehensive guide to accurately measure your cabinets and calculate the paint requirements.

Cabinet Measurement Techniques

Precise measurement involves careful consideration of each cabinet component. Start by measuring the height, width, and depth of each cabinet door, drawer front, and cabinet frame. Remember to account for any intricate details or molding. For doors with raised panels or decorative elements, measure each section separately and sum the areas. For drawers, measure the visible front surface. Record all measurements in a consistent unit (inches or centimeters). It’s helpful to create a sketch of each cabinet, noting the dimensions on the drawing. This allows for a more systematic approach and reduces the chances of errors.

Cabinet Size and Paint Requirements

The following table provides a general guideline for common cabinet sizes and corresponding paint requirements. Remember that these are estimates, and actual paint needs will vary depending on the paint type, number of coats, and the level of surface preparation. Always refer to your paint manufacturer’s instructions for coverage rates.

| Cabinet Part | Dimensions (inches) Length x Width x Height | Surface Area (sq ft) | Estimated Paint Needed (gallons) |

|---|---|---|---|

| Standard Door | 36 x 12 x 1.5 | 7.2 | 0.1 |

| Large Drawer Front | 30 x 15 x 2 | 10 | 0.15 |

| Small Drawer Front | 18 x 10 x 2 | 4.5 | 0.05 |

| Cabinet Frame (per section) | 36 x 12 x 12 | 18 | 0.25 |

Calculating Total Paintable Surface Area

To determine the total paintable surface area, systematically measure each cabinet component. For example, consider a typical kitchen cabinet door: A diagram showing the different parts of a typical kitchen cabinet door, clearly labeled with dimensions. Imagine a rectangular door (36 inches wide x 12 inches high) with a raised panel (10 inches wide x 8 inches high). The total surface area would be calculated as follows: (36 inches * 12 inches) – (10 inches * 8 inches) = 360 sq inches – 80 sq inches = 280 sq inches. Convert this to square feet by dividing by 144 (144 sq inches per sq foot) = 1.94 sq ft. Repeat this process for each door, drawer, and frame section. Sum all the individual surface areas to obtain the total paintable surface area.

Determining Paint Needs Based on Manufacturer’s Coverage

This process involves a simple calculation using the total paintable surface area and the paint coverage rate provided by the manufacturer. The paint coverage is usually expressed in square feet per gallon or liter.

To calculate the amount of paint needed: Total Paintable Surface Area (sq ft) / Paint Coverage per Gallon (sq ft/gallon) = Gallons of Paint Needed

A flowchart illustrating this process would begin with a “Start” box. The next box would be “Measure all cabinet components and calculate total surface area”. Then, a box: “Obtain paint coverage rate from manufacturer’s instructions”. Following this, a box for the calculation: “Total Surface Area / Coverage Rate = Gallons Needed”. Finally, an “End” box. This flowchart provides a clear visual representation of the calculation process. For example, if the total surface area is 500 sq ft and the paint coverage is 350 sq ft/gallon, you would need approximately 1.43 gallons of paint (500 sq ft / 350 sq ft/gallon). Always round up to ensure sufficient paint.

Exploring Paint Types and Coverage Rates: Kitchen Cabinet Paint Calculator

Choosing the right paint for your kitchen cabinets is a crucial step in achieving a beautiful and durable finish. The type of paint you select will significantly impact the final look, longevity, and the overall ease of the painting process. Understanding paint coverage rates is equally important to avoid costly mistakes and ensure you have enough paint for the job.

Kitchen cabinet paint calculator – Let’s delve into the specifics of paint types and how to calculate your paint needs.

Comparison of Paint Types for Kitchen Cabinets

Several paint types are suitable for kitchen cabinets, each offering a unique set of advantages and disadvantages. The following table summarizes the key differences between popular choices.

| Paint Type | Durability | Finish | Ease of Application |

|---|---|---|---|

| Latex | Good; durable enough for most kitchens, especially with proper preparation. Less resistant to scratches than oil-based. | Various; matte, satin, semi-gloss, gloss. Semi-gloss and gloss are most common for kitchens due to their cleanability. | Easy; water-cleanable, low odor. Dries relatively quickly. |

| Oil-Based | Excellent; very durable and resistant to scratches and moisture. A good choice for high-traffic areas. | Various; similar to latex, though often a higher gloss. | More difficult; requires mineral spirits for cleanup, longer drying time, and stronger odor. |

| Enamel | Excellent; known for its hard, durable finish, highly resistant to chipping and scratching. | Typically high-gloss, providing a smooth, easy-to-clean surface. | Can be challenging; requires careful application to avoid brushstrokes. Similar cleanup requirements to oil-based. |

Factors Influencing Paint Coverage

Accurately estimating paint needs requires considering several factors that impact coverage. Underestimating can lead to patchy coverage and require additional coats, while overestimating results in wasted paint and increased costs.

- Number of Coats: Most kitchen cabinet painting projects require at least two coats for optimal color and coverage. More coats may be needed for darker colors or to cover heavily stained wood. Each additional coat increases paint consumption.

- Surface Type: Porous surfaces like unfinished wood absorb more paint than smooth, sealed surfaces. The existing finish (e.g., varnish, lacquer) can also affect paint absorption.

- Paint Viscosity: Thinner paints may require more coats to achieve full coverage compared to thicker paints. The manufacturer’s instructions usually specify the recommended viscosity.

- Application Method: Different application methods (brush, roller, spray) affect paint usage. Spraying tends to use less paint than brushing, but requires specialized equipment.

- Surface Preparation: Proper surface preparation, including sanding and priming, is essential for optimal paint adhesion and coverage. Skipping these steps can increase paint consumption and lead to uneven results.

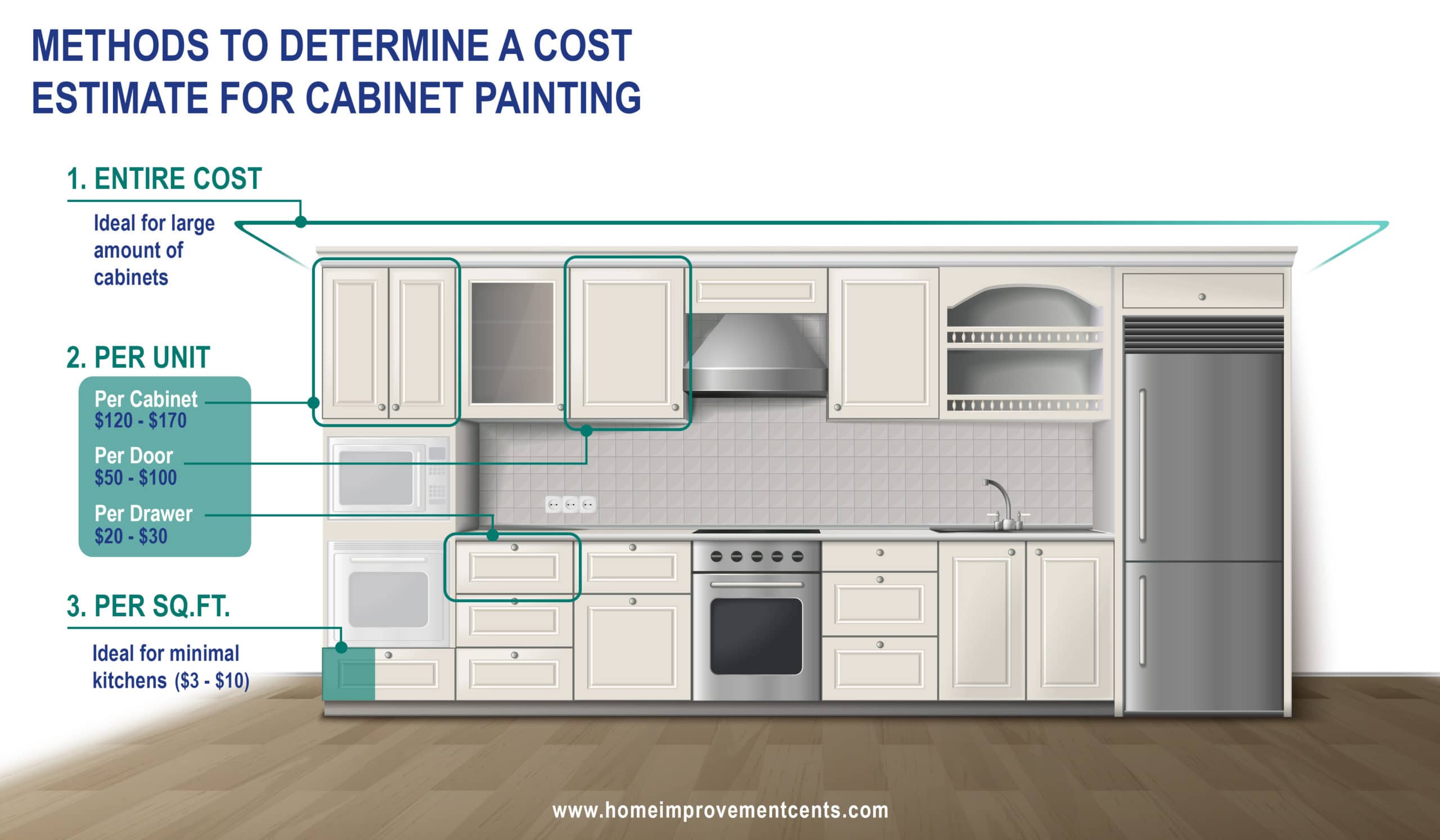

Sample Paint Calculation, Kitchen cabinet paint calculator

Let’s assume we need to paint 100 square feet of cabinet surface area. The chosen paint has a manufacturer-specified coverage rate of 350 square feet per gallon. The formula for determining paint needs is:

Total Gallons Needed = (Total Surface Area) / (Coverage Rate per Gallon)

In this example:

Total Gallons Needed = 100 sq ft / 350 sq ft/gallon ≈ 0.29 gallons

Since paint is typically sold in whole gallons, we would need to purchase one gallon of paint to ensure complete coverage. Always round up to the nearest whole gallon to avoid running short.

Practical Application and Refinement of Estimates

Accurately estimating paint needs for your kitchen cabinets isn’t just about the numbers; it’s about understanding the nuances of the painting process and ensuring you have enough paint to complete the job smoothly. This section delves into practical considerations to refine your initial estimates and avoid costly mistakes. We’ll explore how to account for inevitable waste and ensure you have sufficient paint for a professional-looking finish.

Estimating paint for a project like repainting kitchen cabinets requires more than just a simple calculation. You need to factor in real-world scenarios that can easily lead to needing more paint than your initial calculations suggest. This is where adding a buffer becomes crucial.

Accounting for Waste and Overage

Unexpected spills, uneven application, and the need for touch-ups are all realities of painting. To account for these variables, adding a percentage buffer to your calculated paint amount is essential. A good rule of thumb is to add 10-20%, depending on your experience level. For beginners, a 20% buffer provides a comfortable safety net. For experienced painters, 10% might suffice. Let’s illustrate this with an example. Imagine your calculations indicate you need 2 gallons of paint. Adding a 15% buffer would mean purchasing an additional 0.3 gallons (2 gallons x 0.15 = 0.3 gallons). It’s always better to have extra paint on hand than to run short mid-project. This prevents the need for color matching later, which can lead to noticeable differences in the final result. Think of it as an insurance policy for a flawless finish.

Adjusting Paint Quantity for Multiple Coats

Most painting projects require multiple coats for optimal coverage and color depth. The number of coats needed depends on the type of paint, the color you’re using, and the condition of the cabinets. For example, painting over dark colors with light colors often necessitates more coats than painting similar shades. Remember to adjust your total paint quantity accordingly. If your calculations suggest 2 gallons for one coat, and you plan for two coats, you’ll need at least 4 gallons, plus your waste buffer. Failing to account for multiple coats is a common mistake leading to paint shortages.

Painting Timeline and Drying Time

Proper planning includes accounting for drying time between coats. This allows the paint to fully cure, ensuring adhesion and preventing issues like peeling or chipping. A typical drying time between coats is 4-6 hours, but this can vary depending on the paint type, temperature, and humidity. Here’s a sample timeline for a two-coat paint job:

Day 1:

* Morning: Prepare cabinets (cleaning, sanding, priming if necessary).

* Afternoon: Apply first coat of paint.

Day 2:

* Morning: Allow sufficient drying time (at least 4-6 hours).

* Afternoon: Apply second coat of paint.

Day 3: Allow for final curing.

This timeline is flexible and can be adjusted based on your specific needs and the drying time recommended by your paint manufacturer. Always refer to the manufacturer’s instructions for accurate drying times. Rushing the process can compromise the quality of the finish.